High Purity Silicon Carbide

(HP-SiC)

Materials

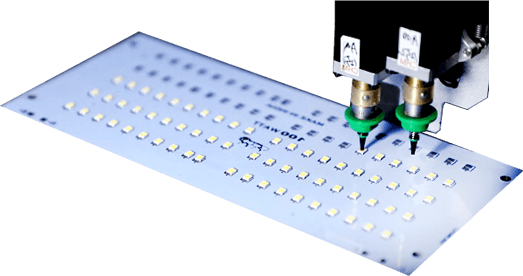

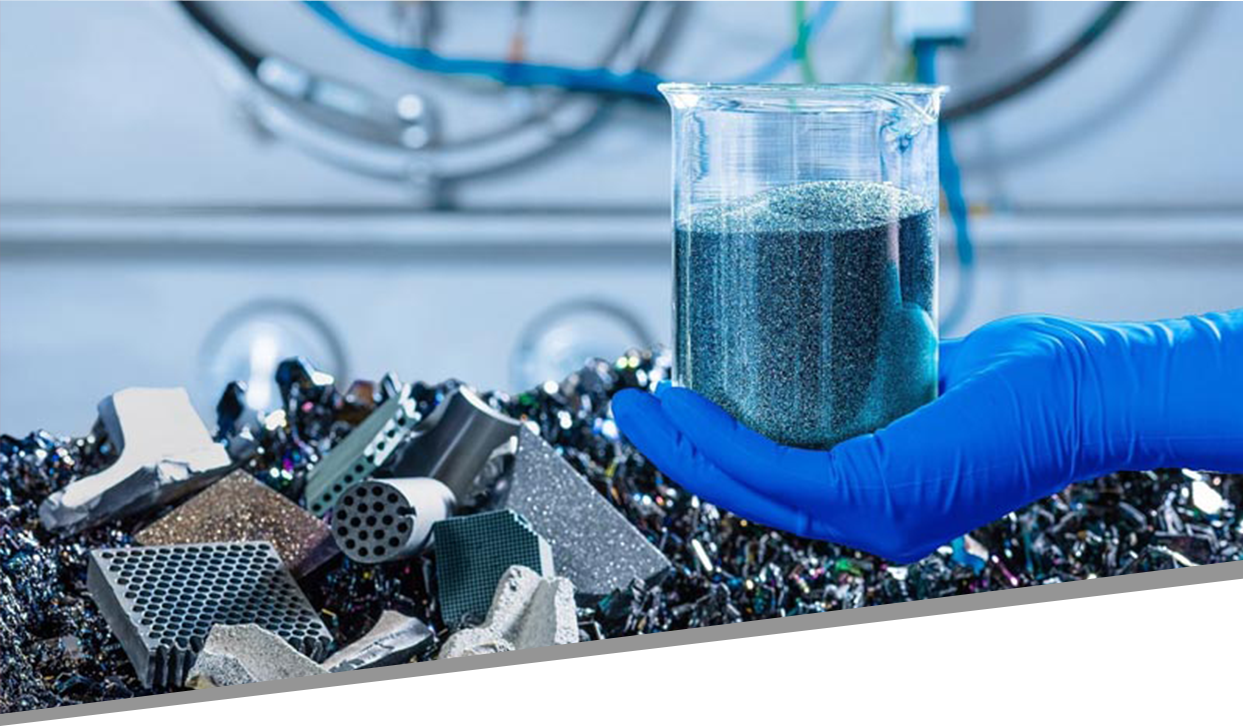

Welcome to the next evolution in material science. At SNAM Abrasives, we are proud to introduce our new line of ultra High Purity Silicon Carbide (SiC) - SNAM Amala ® HP-SiC – a product designed to meet the demands of the most advanced applications across various industries. With decades of experience in manufacturing and globally selling silicon carbide of all grits, properties and specifications, we now bring you a product that exemplifies excellence, precision, and unmatched performance.

Developed after extensive in-house R&D and multiple trials, SNAM Amala ® High Purity Silicon Carbide (HP-SiC) can be tailored to customer needs for 3N or 4N purity. [3N Purity = 99.9% High Purity SiC, 4N Purity = 99.99% Ultra High Purity SiC]. Given the ultra high purity levels of Silicon Carbide, traditional methods to test SiC purity cannot be used, that's why SNAM Amala ® High Purity Silicon Carbide is tested for trace elements using Glow Discharge Mass Spectrometry (GDMS)

.png)

.png)